Die-Cutting and Your Print Job

Professional Die-Cutting

Die-cutting is a great finishing method that can help your project stand out from standard printed pieces. The die-cutting process is used to cut paper into any shape that’s not a square or rectangle, and it can create custom sizes or shapes that are completely customized to your project.

Whether it’s grand opening invitations shaped like your company’s logo or packaging labels shaped like a star, adding die-cutting to your project requires a little bit of additional planning and details before it’s ready to print. Knowing how to set up die-cutting in your print job can help strengthen the communication between you and your printer, and ensure that you’re getting an end result that you’re proud to show off.

What Can Die Cutting Add to my Print Job?

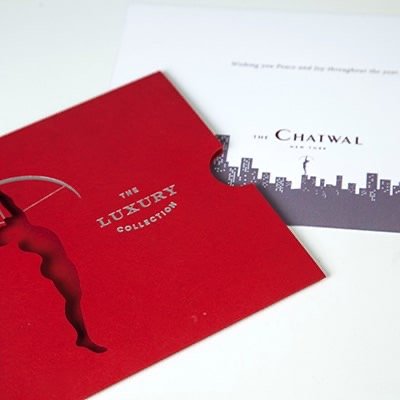

There’s not a lot to be said about projects that are shaped like squares or rectangles, but the custom shapes that can be created with die-cutting can add crisp edges and a creative appearance to your print job. Die-cutting can also be combined with colors and other print options like embossing to create a truly striking work of art.

With die-cutting, the options are almost limitless. At Thomas Group Printing, we are highly trained and experienced in multiple types of professional print services, including die-cutting for a wide variety of companies and projects.

What Types of Projects Can Benefit from Die Cutting?

Just as there are a wide range of designs you can create with die-cutting, this process can also be applied to several different kinds of projects, including:

- Packaging

- Invitations

- Brochures

- Pocket folders

- Display work

If you don’t see your anticipated project in this list, a professional printer can discuss your vision with you and let you know if die-cutting would be appropriate for your print goals.

How Can I Prepare for my Die Cutting Project?

Prior to the die cutting process, it is important to discuss the area you would like die-cut with your printer to ensure that the die cut will work for your particular artwork. Certain shapes and angles are not attainable when die cutting. When it comes to setting up a die-cutting process, most of the set up takes place on the printing end. The letterpress machine is loaded with steel cutting blades that are shaped to your design specifications, and the paper fed through and cut on specialized machinery, one sheet at a time. The dies are designed with tiny “nicks” that keep the die-cut designs attached to the press sheet until it reaches the end of the printing process. This way, the cut shapes do not fall into the machinery.

On the customer end, setting up a die-cut design for the printer only takes a few additional steps. At Thomas Group Printing, when we ask for a die file, we ask that the designer send us the area that they desire to be die cut as a separate file in black, which we call a black negative. When planning on using die cutting for a printing piece, it is important to reach out to your printer ahead of time to discuss the timeline for die cutting since this is an extra step to the print process.

It is also important to note that the printer has to order a die, so please consider adding a day or two to the production process. Most printers like to get the area that is meant to die cut ahead of time so they can place the order for the die. The cost of die-cutting is typically determined by size and detail, but as a good rule of thumb – the bigger the design is, the more expensive it may be. Your printer can also suggest adjustments to help make your design more feasible for your budget.

At Thomas Group Printing, when we ask for a die file, we ask that the designer send us the area that they desire to be die cut as a separate file in black or outlined in magenta.

The finished product

Get Started On Your Die Cutting Project Today

Deciding to add die-cutting to your project can also add more steps and cost to your print project, but your professional printer is there to help you make it work so you can achieve the best results. Ask your professional printer about die-cutting to get started on your next big project.

I work for a printer. Please be sure your die lines are in a spot color and they Overprint.

Thanks!!

I created some new, circular business cards a year ago, and despite working in and around the industry for decades, was astonished that a die cut would add $1,000 to the price of the job. And it didn’t matter how many vendors I inquired with, the price was roughly the same everywhere.