Reducing Total Ink with Selective Color Adjustments in Photoshop

Learn how to get better print results using a nondestructive layer adjustment.

In the world of print design, the end of the design phase is just the beginning of the prepress phase. Creatively, you may be finished with a piece, but next you must ensure that the file is ready to print as intended.

Most printers will be happy to provide specifications for how to submit files. Their goal is the same as yours: to save time and money, deliver the project on schedule and with the best possible results. Following their specs will get you there. And using a prepress checklist before you submit your file to the printer can prevent your project from getting bounced back, and/or the printer having to fix your files, which will usually incur additional costs!

Having been in print production for over 25 years, I use a prepress checklist before submitting my files to the printer or imposing them myself for press. One of the items on my checklist is confirm (or fix) the ink density in my images, so I’m sure it’s within the limits my printer has specified.

What is Ink Density?

First let’s understand what is meant by ink density.

When several colors are printed on top of each other, there is a limit to the amount of ink that can be put on paper. This maximum dot percentage is referred to as either TIC (Total Ink Coverage) or TAC (Total Area Coverage).

What happens when a designer ignores this ink limit? The ink that gets laid down on press last will attach improperly to the previous layers and it will not dry properly on the press sheets. This is referred to as off-set, where the ink of a still wet sheet rubs off on whatever is stacked on top of it. Believe me, this is one mess you want to avoid. So let’s see how to do that.

Specifications for Total Ink Coverage

Percentages are used to describe ink coverage. So if you had the maximum 100% of C, M, Y, and K, you’d have 400% TIC, which is equivalent to the Registration swatch in a CMYK InDesign file.

Several factors determine the maximum amount of ink that will work for a particular job, including:

- The printing process: offset (sheet fed or web), digital, and so on.

- The paper being used (coated vs. uncoated stock)

- The number of inks being used in one press run

- The physical characteristics of the press itself, including its speed

Not correcting ink density can also result in muddy looking neutrals where the mix of cyan, magenta, and yellow creates an unpleasant brown color where there should be neutral gray.

While it is always is best to ask your print service provider what TIC/TAC they recommend, the following percentages are industry averages and can be used as a basic guideline.

- Sheetfed offset on coated paper (typical commercial printing): 320%

- Heatset web offset (such as magazines): 300 to 320%

- SWOP: 300%

- FOGRA39: 300%

Measuring Ink Density

So how do we measure ink density in our files?

If you’re working in Photoshop you can use the Eyedropper tool and the Info panel. I customize my Info panel to always display Total Ink in the top right section. Here’s how:

- Go to the Info panel flyout menu and choose Panel Options.

- Change the second color readout to Total Ink. Notice the Sigma (the symbol for sum) next to the second eyedropper icon.

- You can also toggle the arrow under any eyedropper and change the readout(s) on the fly.

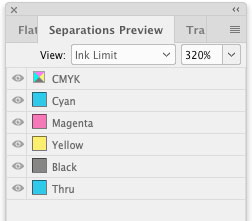

If you’re working in InDesign you can check total ink in the Separations Preview panel (Window > Output > Separations Preview). Set the View menu in the panel to Ink Limit, and then adjust the total percentage to your specific output requirements.

Need to check the total ink in an Illustrator graphic? There is no equivalent to InDesign’s Separations Preview panel, but you can simply place the Illustrator file into an InDesign layout and check the ink numbers there. Or open the file in Adobe Acrobat and use the Output Preview panel, found in the Print Production tools.

You can see the ink percentages for a chosen simulation profile and highlight any areas that are over a specified TAC.

How to Adjust Ink Density in Photoshop

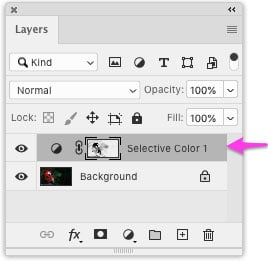

My favorite way to adjust ink density in Photoshop (which is nondestructive, of course) is using the Selective Color Adjustment. My method is similar to the GCR (Gray Component Replacement).

I pull similar amounts of cyan, magenta, and yellow out of the darkest areas and compensate by putting half as much black back in. This reduces the overall TIC/TAC and ensures me of the results I want on press.

Here are the steps:

- First make sure that your document is in CMYK mode.

- In the Channels panel, target the black channel and make a selection from it using the selection button at the bottom of the panel.

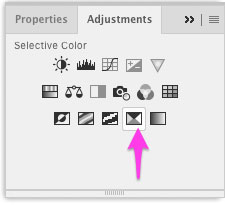

- With the selection active (you will see the marching ants), go to the Adjustments panel and choose the Selective Color adjustment.

- This will make a new layer with a layer mask.

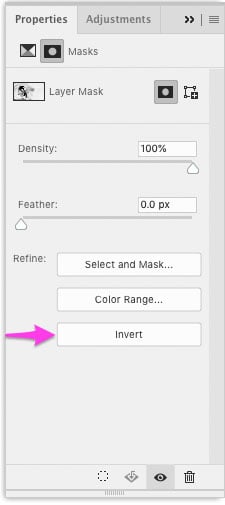

- Click on the mask thumbnail, then go to the Properties panel and click the button to invert the mask.

Remember, when it comes to masks, “black conceals and white reveals.” Your mask should be lighter in the darker areas of the image.

- Go to the black color channel of the Selective Color adjustment and enter these values to start: C: -8, M: -8, Y: -8, K: +4. Then check the total ink to see if it’s below the maximum for your print job. If not, reduce the C, M, and Y and increase the black further.

- Always adjust the values equally. So if double the C, M, and Y adjustment to -16 each, you must double the amount of K adjustment to +8 to compensate.

You can see that the ink density in the above image was effectively (and nondestructively) adjusted to be under 320%, by looking at the before and after values in the Info panel.

If you really want to get fancy you can create an action to perform all of these steps. But that is a story for another time!

This article was last modified on August 10, 2021

This article was first published on August 9, 2021

Commenting is easier and faster when you're logged in!

Recommended for you

Working With Spot Colors

Claudia McCue's guide to everything you need to know about designing and printin...

Save and Export Photoshop Files Effectively

Save, Export, Generate… Photoshop gives you so many ways to save files. How do y...

InDesign Magazine Issue 122: Cross-Media Color

We’re happy to announce that InDesign Magazine Issue #122 (June 2019) is no...