Fixing CMYK Images Over Your Ink Limit with Photoshop

Learn how to lower total ink in an image and still get the best results for your output conditions.

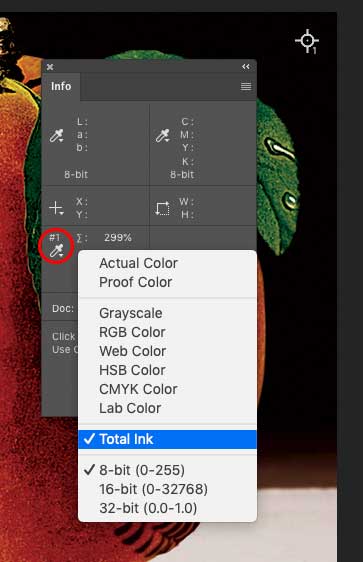

Here’s a prepress problem: You have a CMYK image in which the Total Ink Coverage (TIC) is over the press limits for successful print. What does this mean? If you somehow piled up the combination of C100-M100-Y100-K100, that adds up to 400% ink. Even in a very dark image (think: darkest outer space), I doubt you’d ever encounter that. But if you know your image’s destination, you should find out your current TIC to see if it’s satisfactory. In Photoshop, you can use the Info panel (Window > Info) to view TIC. I like to start by using the Color Sampler Tool (hidden behind the Eyedropper Tool in the Toolbar) to place a static sampler. Click in the image to set a sample point. You can drag it to move it, or hold Alt/Option and click it to delete it. Once you have the sample point where you want it, click the teeny, tiny arrow by the sampler icon and choose Total Ink from the menu. Then you can see what’s really going on.

Viewing Total Ink in the Info panel

Here are two options.

Method One: Convert Directly to Another CMYK Profile

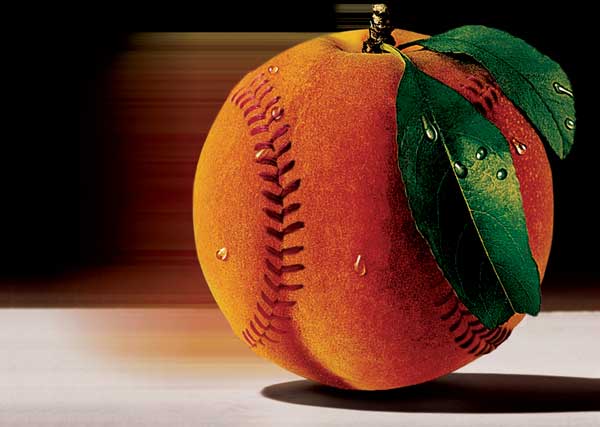

Here I have an image with a dark black background, which maxes out at C85-M78-Y77-K100—a TIC of 340%.

Original: 340% total ink

- In Photoshop, choose Edit > Convert to Profile and pick a suitable profile. In my example, I need this image for a job running on a web press on newsprint, so I choose the US Newsprint (2007) profile.

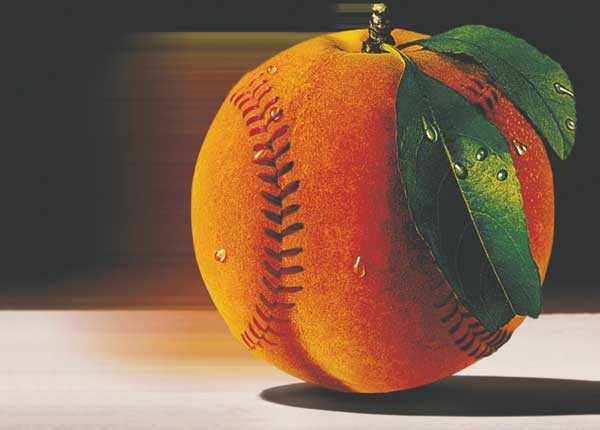

- Poof! My max ink pile is now C55-M45-Y48-K71, for a TIC of a svelte 219%. However, some areas of the image now look sort of anemic; the color is really washed out.

CMYK-to-CMYK: Convert to Profile: 219% total ink

Method Two: Convert to Another CMYK Profile via LAB

This method forces a re-separation of the image. But don’t be tempted to go to RGB, then back to CMYK. Instead, use Lab (or L*a*b*, or however you like to express it) as the intermediate color space. Why? Well, it’s Photoshop’s internal “mental color space.” Going through Lab (I’m tired of typing asterisks) is lossless.

- Duplicate the image for safety’s sake (and to have a reference for comparison).

- Convert the new image to Lab: Image > Mode > Lab Color. You’ll see no change in the on-screen appearance.

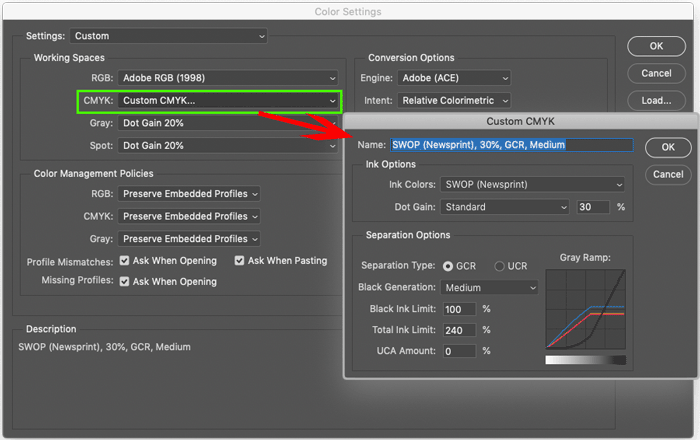

- Create a custom separation setup. Again, in my example, I need to convert a heavy-duty image with a TIC of 340% into an image suitable for newsprint, with a TIC of 240%—quite a color diet. Here’s my recipe: • Choose to Edit > Color Settings. • In Working Spaces, click the CMYK pulldown menu, push up to the top, and choose Custom CMYK. • For Ink Options, I chose SWOP (Newsprint) and Standard Dot Gain. • Because my image has a lot of solid black areas, I chose Medium Black Generation, a Black Ink Limit of 100%, and a Total Ink Limit of 240%, and clicked OK. Note that your choice of inks will be based on the press running your job.

- Now just choose Image > Mode > CMYK. Your new custom separation setup will be used as the recipe.

Creating the Custom CMYK for Method Two.

CMYK-to-Lab-to-CMYK: Custom Profile: 240% total ink

While the Convert to Profile option (Method One) did the job, the color is anemic. Color will be a bit heavier when ink hits paper, due to dot gain, but I like the results from my custom profile better (Method Two).

While the Convert to Profile option (Method One) did the job, the color is anemic. Color will be a bit heavier when ink hits paper, due to dot gain, but I like the results from my custom profile better (Method Two).

Using Separations Preview in InDesign to spot ink limit problems

InDesign can tip you off to potential ink limit problems with its Separations Preview Panel (Window > Output > Separations Preview). In the panel, choose the Ink Limit from the View menu, and set the value to your desired max TIC—in this case, 240%. Remember that a little “peppering” of heavy ink isn’t a problem, but large areas (as the original image would have produced) would be unwieldy on press.  This article is for CreativePro members only. To continue reading, please log in above, or sign up for a membership today! Thanks for supporting CreativePro!

This article is for CreativePro members only. To continue reading, please log in above, or sign up for a membership today! Thanks for supporting CreativePro!

Commenting is easier and faster when you're logged in!

Recommended for you

InDesign to Print & Screen: A Best-of-All-Worlds Workflow

When the output could be PDF, EPUB, or print—or all three—there’s no need to com...

How to Convert Fonts to Outlines in a PDF

If you need to provide a PDF with fonts converted to outlines to your print serv...