Between the Sheets

Quark Imposer, part of the Quark Print Collection, has settings for five types of imposition: traditional sheetwise (which it calls standard), work-and-turn, work-and-tumble, split-web, and a sheetwise defined differently from traditional sheetwise. If you’re a little rusty on your imposition, read this explanation of the most common types.

Sheetwise Imposition

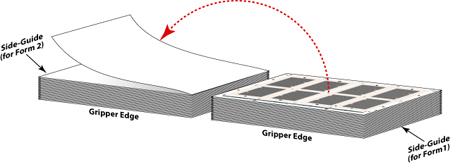

The simplest of imposed signatures are produced by printing one side of the press sheet, then turning the sheet over and printing the other side. This puts each page on the back of its predecessor. This process allows the press to hold each sheet by the same gripper edge, and to register that sheet side-to-side with the same side guide. (This requires that the press pull the sheets to register on opposite sides of the machine between sides).

This most basic process is called sheetwise imposition (Figure 1). It requires one set of printing plates for each side of each signature.

Figure 1: Sheetwise: After printing one form (side), the paper is flipped, and the other form is printed. The Gripper Edge remains the same, as does the Side-Guide (though it is now on the other side of the press). Press register from form-to-form is assured with this method of printing. To see a larger version of this image, click on it.

Work-and-turn imposition

When the run-length of a project is short, and the number of pages is evenly divisible by four, a printer may arrange a signature into two forms (a form is one side of a signature), and then print the two forms front and back on the same side of the press sheet. This is called work-and-tumble printing.

With work-and-turn runs, the number of press sheets printed is half the total run. The printer will print one side, then turn it over and print it again, front-on-back, and back on front. After the ink dries, the printer will cut the sheets in half, splitting them into two stacks of paper – finished signatures – that are ready for folding and binding.

Work-and-tumble impositions are used when the side-guide on the press can’t be switched to the opposite side. The paper is printed, flipped, and rotated 180 degrees (Figure 2). The Gripper Edge changes, but the Side Guide remains the same. Work and tumble printing is not too common, but occasionally it’s the only way to solve a printing or binding problem.

Figure 2: Work-and-tumble: After printing one form (side), the paper is flipped and rotated 180 degrees, then the other form is printed. The Gripper Edge changes, but the Side-Guide remains the same. Press register from form-to-form is less reliable with this method of printing. To see a larger version of this image, click on it.

Work-and-turn impositions require only one set of plates, so for some jobs it is less expensive and more efficient. The benefits are that the gripper edge remains constant and the same side-guide is used for both sides (necessary for good register on press). The job is also less expensive because the plates stay on the press, reducing the labor involved in changing them.

Return to the main article, “Review: Quark Print Collection.”