Printing World: Profit Anglers

Sir Speedy owner Phillip Huepenbecker says that although only about 30% of his digital printing business is four-color reproduction, it supplies the “wow” factor. He reminds us of the proven maxim that color sells. Huepenbecker ought to know; he worked his way through college running packaging presses printing cereal boxes. But today, digital printers angling for decent profits in a world where offset four-color has become a commodity, bait their hooks for the big ones with value-added reproduction.

Obviously, choosing to go digital or not is left to individual printers to decide, dependent upon their specific needs, not the mainstream’s. Still, it’s difficult to argue with success, and many printers may soon decide to “follow the leaders.” Here’s a look at some current offerings:

The samples of digital color printing reproduced for this story indicate that on-demand printers are becoming as wily as fly fishers when it comes to developing profitable business opportunities. Take the top three winners in Xeikon America’s second annual U.S. Diamond Awards. There were wallpaper borders of exquisite print quality, available on the Internet in 40 different designs, customized 10-page auto comparison guides consumers can order from a Web site and receive within 48 hours, and a program that allows real estate agents to order some 20 customized items.

These striking examples do not imply, however, that “plain vanilla,” short-run, four-color, reproduction included in our Gallery is not a profit center in an on-demand shop that offers a mix of services. They are an indication, though, that printers with digital presses are beginning to find the market receptive to products suited to their technology. They are also an indication that designers are becoming increasingly aware of the power of on-demand digital printing.

Dan Price, president and creative director, and partner Rick Fillmon of Denver’s Adrenalin Design, who allowed us to use segments of their fish poster designed for IBM Digital Printing for this story, have been ordering jobs on digital presses for six years. “We use digital presses when the quantities are right,” Price says. “Right now, that’s about 10% of the time. As long as it’s the right fit, it’s the way to go.” He sees both straight four-color short runs, especially projects with tight deadlines, and multiple-page short runs as particularly viable. The aptly named shop specializes in graphics for the sporting world and began working with IBM three years ago when Big Blue needed an Olympic poster. Subsequently, Adrenalin has produced a number of demonstration projects for IBM to print on the InfoPrint models 70 and 100.

As to quality of reproduction compared to offset, Price recalls that he became confident in digital printing about three years ago. Now, he believes that results still depend on what’s in the file-designs with lots of texture in the background work well, big solids are still problematic. Given that caveat, he says, “It’s getting to where it’s hard to tell the difference.”

The Gallery

Fort Dearborn Digital

Fort Dearborn Digital Printing capitalizes on the Xeikon’s ability to print continuous images more than 12-feet long. Its wallpaper borders garnered a Xeikon Diamond Award last spring as Best New Application.

According to industry statistics, retail sales of traditional wallpaper have dropped 20% since 1990. However, sales of wallpaper borders have steadily grown and now account for more than 50% of a $1.6 billion market. Digital color print production has opened the door for creative entrepreneurs to exploit this trend by employing new business concepts. With long-format digital printing, designers can create mural-style artwork wallpaper borders that can be printed in runs to meet market demand. Companies can also offer customized border designs for corporations and consumers. Someday soon, you’ll be able to order a border with the family dog on it for a child’s room.

Fort Dearborn’s very real business came from partnering with 4walls.com, a “virtual” wallpaper border company based in Cleveland, to develop the trademarked Surround Borders-more than 50 different designs that can be ordered via the Internet from the company. Fort Dearborn prints rolls of prepasted wallpaper borders 12.5 feet long. The company also worked closely with 4.walls.com’s design firm, DLM Studio, to develop a proprietary coating that ensures a smooth finish.

The concept was introduced on-line last spring, with a limited marketing program. Just a few months later, 4walls.com signed agreements with two major distributors, whose 80-plus representatives began selling Surround Borders to high-end retail outlets in the United States and abroad starting in February. Fort Dearborn printed 5,000 sample books to support this major sales initiative and expects to run up to 10,000 rolls per month soon.

Elements Inc.

New York City’s Elements took a Xeikon Diamond Award for its work with the RE/MAX worldwide network of 44,000 real estate agents. Named the Best Print on Demand Application, this project allows agents to order customized communications from a RE/MAX catalog featuring brand-name templates for products such as brochures, direct-mail pieces, key chains, magnetic refrigerator signs, “we’ve moved” cards, thank you notes, and even aprons. Items can be modified to include a picture of the client’s new house, or other customer-specific information printed on the Xeikon DCP/32/D. According to Elements, some 1,000 agents already have participated in the program, with 30 to 40 orders per month coming from virtually every state, as well as Germany, Israel, Canada, and other countries. The average run length, depending on the product, is one to 4,000, with a three-day turnaround time.

Moore Interactive Marketing Solutions

A personalized, 10-page “New Car Buyers Workbook” from Moore Interactive Marketing Solutions in Grand Island, NY, took the Xeikon Diamond Award for Best Direct Marketing Application. Edmund’s, publishers of automobile information, has set up its web site so that car buyers can select the content (models, photos, vehicle comparisons, and more) and receive a customized booklet within 48 hours. Edmund’s generates revenue from each workbook, and Moore reports receiving up to 100 orders a week.

Face Creative Services Ltd.

Worldcom was laying telecommunications cable through the streets of London and wanted to add new customers to build in the requisite carrying capacity and maximize revenues. To personalize their message and let potential customers know that they deliver advanced telecommunications, the company had 16 main building entrances photographed. Then the appropriate image and text was placed on the cover of a mailer printed on Agfa’s Chromapress. Prospects received a target mailer with a full-bleed image of their own building entrance on the cover for maximum effect. This short-run, variable-data job consisted of 300 pieces, each with one of 16 building fronts and individualized text.

Sir Speedy Goes Regional

Phillip Huepenbecker and his family run Sir Speedy in Lancaster, PA, in addition to owning shops in Harrisburg and Camp Hill, PA. In November 1996, Huepenbecker installed a Quickmaster DI in Lancaster, and today offers digital printing to some 80 Sir Speedy franchises through east-central Pennsylvania, New Jersey, and Washington, D.C. “Not all of these shops can purchase a DI,” Huepenbecker says, “so we serve as a production center, with over 30 shops continually using the service. We get files over the Internet and on disk.”

In addition to an array of small, single or two-color conventional presses, Huepenbecker also runs a Canon CLC and a wide-format Encad device. But nearly all four-color work is done on the QM-DI, with average run lengths of 2,500.

“We can do four-color for the price of three,” he says. “In our marketing, we’re stressing speed, plus real offset printing on any substrate from letterhead to 12-point board. We’re running the Quickmaster for 20 hours most days, and we may be adding another in the near future. We see strong, continued growth in the color market.”

R&R Images Inc.

For Rodney Key, president of R&R Images, Phoenix, the Quickmaster DI meant a change in business. Fourteen years ago, R&R opened as a commercial photography studio and about seven years ago acquired its first Leaf digital camera back. That put them on the digital route, but because no one else in Phoenix was handling digital color, they ended up buying their own scanner and imagesetter and hiring a designer for prepress. “Two years ago we purchased the QM-DI. It was a big move up the ladder for us,” Key says. “However, although our photography and film business was very good at the time, I could see that in two to five years, we would be in trouble. We were one of the first in town to install the Quickmaster, and we remain the leader in producing the highest quality work. Our skill with images evolved from photography. We’re not the cheapest in town either, but we are competitive. We do general commercial work for any size company and our sales force brings in jobs that include photography, design, and printing.”

Typical runs are around 1,000 impressions with same or three-day service. Key describes one repeating project for a major corporation that involves books for its national sales meetings. “These have some tabbed pages, and die-cutting, and the customer wants these pieces to be spectacular. Usually, we run 500 books of 20 to 30 pages in two days from start to finish. We always wonder how they did it before digital printing. You can’t image film and print in the turnaround times we’re allowed,” Key says.

Conlin’s Copy Center

With three locations in the greater Philadelphia metropolitan area in King of Prussia, Malvern, and Horsham, Conlin’s Copy Center is a prototype on-demand printer. The family-owned company has two Xerox 6180s, three DocuTech 135s, three 50-inch wide-format Encad NovaJet Pro 50s, two 36-inch NovaJet IIIs, five Canon CLC 1000s, two CLC 2400s, and three CLC 800 copier/printers for color work. There are also a number of other Xerox high-speed copiers and a full bindery that includes wide-format finishing and several Océ wide-format engineering copiers. In addition to on-demand digital copying and printing, Conlin’s acts as a facilities management service with its own equipment installed at customer sites. It ranks as one of the top 10 copy centers in the United States.

“We do work for everyone but because of our location, we have a great many designers and agencies as clients. We run packaging prototypes, performance pie charts, manuals, flyers, and so on,” says Production Manager Bill Conlin. He notes that most runs on the CLCs are under 1,500 impressions. Beyond that, the company brokers color to another area digital printing firm with a color press. Conlin also says that typically their color jobs will have “lots of originals,” perhaps 20 sets of 50 pages in color for a sales presentation. Same day/next day service is the norm here. In addition, Conlin’s serves international corporations and ships worldwide on a daily basis.

eprint inc.

Dave Watry’s Stockton, CA, company used to be called DW Graphics. Redesignated eprint inc. recently, Watry says the new name reflects “more of what we do.” Color printing here is done on a Xerox DocuColor 40, with a goal of offering “commercial quality that matches offset.” Watry says that the company succeeds frequently because they use GCR and color profiling available on their Scitex SX 3000 front end. “The trick is to get the toner to lay flat like offset ink,” he explains. “With heavy coverage, it’s impossible though. But on business cards, for example, you can reduce a 100% yellow to a 90% tint. It lays flat and you won’t know the difference.”

Although eprint prints plenty of brochures and sell sheets, business cards are its bread and butter. “We print a ton of them – 20,000 a day,” Watry says. He also reports that the company has begun to offer variable-data printing on the DocuColor 40, using Scitex Darwin software as the building tool. “It’s still hard selling these jobs,” he admits. “People are not beating down the doors for this work yet.”

Indigo’s Coup

Last fall, Indigo, the manufacturer of digital color printing systems that include the E-Print and Omnius family, and Hallmark Cards Inc., the $3.9 billion gift and stationery industry giant, announced a relationship to incorporate Indigo digital printing technology for proofing and producing Hallmark greeting cards. In addition, Hallmark is exploring the use of Indigo’s printing technology for selected applications.

As part of the announcement, Indigo revealed that Hallmark first used its equipment to proof its Warm Wishes, a new line of 99-cent cards introduced in November 1998. Indigo’s six-color printing capability was combined with Hallmark BigBox Color, a trademarked production process that uses proprietary inks to reproduce a greater range of color with vivid intensity. Digital proofing enabled the company to keep the Warm Wishes production process completely digital.

Pharmaceutical Applications

Since health care makes up a significant percentage of the world’s economy, it’s no surprise that sophisticated one-to-one marketing campaigns using the variable-data capabilities of digital presses are taking root in the industry. One set of figures says that major pharmaceutical companies spend nearly $6 billion in sending more than 56,000 full-time sales representatives into doctors’ offices and hospitals to disseminate educational information about their products. Three recent projects show the potential for printers in this vertical market.

ColorStream Technologies in Chicago runs an IBM InfoPrint 70 in an all encompassing facility that prints and consults on marketing materials, maintains virtual databases with up-to-date consumer information, and helps clients turn data into valuable marketing information. According to president George Willock, ColorStream is helping its customers achieve a qualified buyer return rate of more than 10%.

In one such project for a pharmaceutical company, ColorStream customizes marketing pieces designed to inform physicians, HMOs, and healthcare facilities about medications relevant to their patients. Mailers are personalized with the physicians’ details, information relating to the physician’s specialization, and the healthcare facility’s logo.

New York-based Elements, the Diamond Award winner for its RE/MAX work, also uses its Xeikon DCP/32D on an impressive project for Pfizer, the $13.5 billion pharmaceutical manufacturer. Pfizer’s sales representatives can use their laptop computers to design and create sell sheets, four- and six-page brochures, and patient cards based on their customers’ specification. Elements offer these representatives 56 different templates for some 25 different drugs and ships managed care organization-branded materials to their customers within three days.

Lastly, Amsterdam-based Virtual Literature Management (VLM) provides a full range of digital color printing solutions on its Agfa Chromapress. Among the company’s many variable-data projects, VLM is producing an ongoing European stop smoking project for SmithKline Beecham. The U.S. version has been concluded. Summarizing, SmithKline Beecham created a sophisticated set of personalized publications delivered to smokers who contact their call center. In all, participants receive 10 communications from the company, with one-third of the data completely variable. In Europe, to further complicate the project, these materials are produced in four languages for around 8,000 to 10,000 participants a month. According to Agfa, SmithKline Beecham more than doubled its market share in less than three months, with a 250% growth in the nicotine replacement patch market in Britain alone.

Noel Jeffrey is the executive editor of Quick Printing’s sister publication, Print on Demand, in which this article first appeared. She may be contacted at: ed****@**db.com

Copyright 2000 PrintPlace.com, Inc. All rights reserved.

This article was last modified on January 6, 2023

This article was first published on May 1, 2000

Commenting is easier and faster when you're logged in!

Recommended for you

Buying a Color Printer

There’s something compelling about seeing your work in print. That holds true ev...

Scanning Around With Gene: PageMaker Memories from 6 to 72 Point

There is a Salvation Army store that happens to be on the way to my bank, both o...

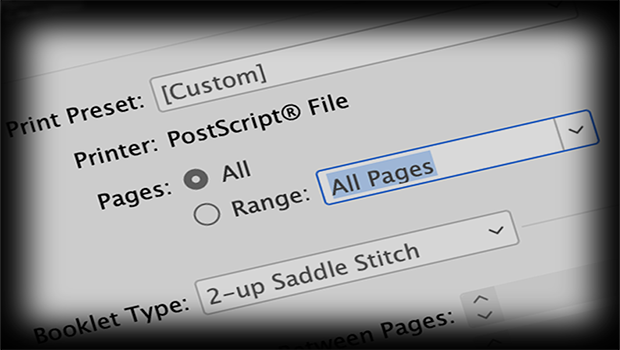

Creating a PDF from InDesign’s Print Booklet Feature

A step-by-step guide to creating a PDF of printers spreads with Print Booklet.